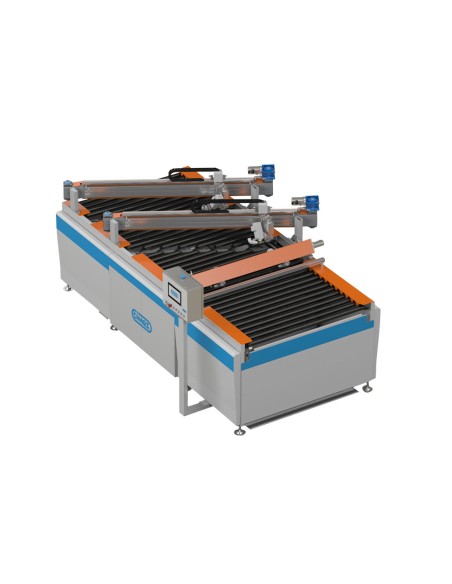

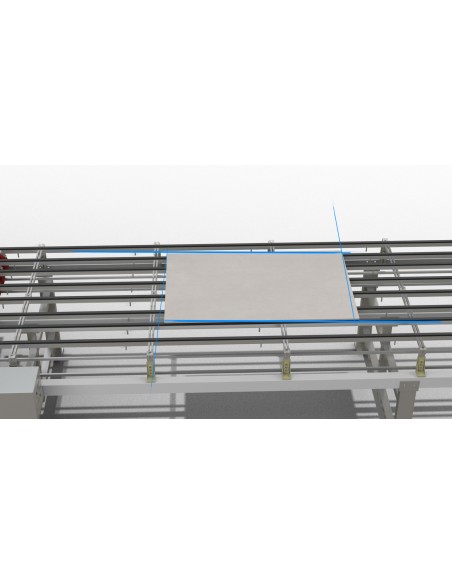

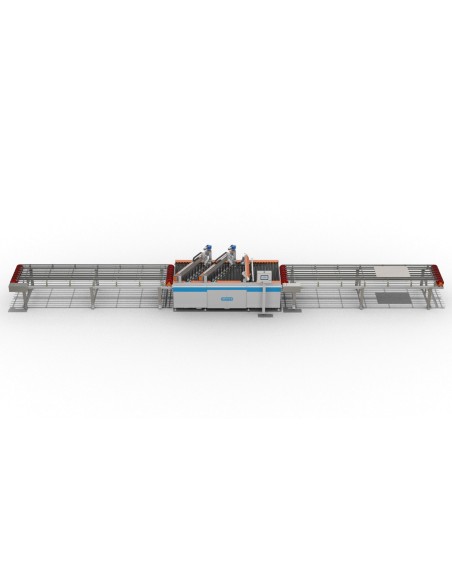

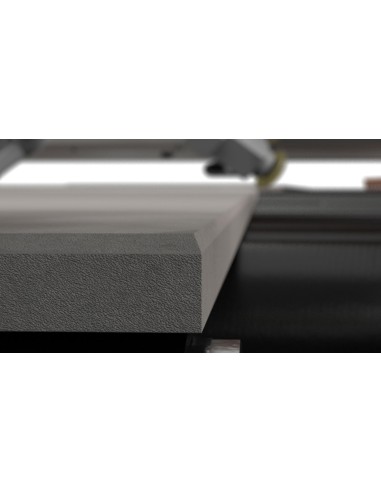

This system was developed to address the global need for automating traditional deburring processes. It is the world’s first deburring machine capable of continuously cleaning all four sides of slabs and tiles. It ensures a consistent feed, maintaining uninterrupted production without the need for stopping, guiding, or centering phases.

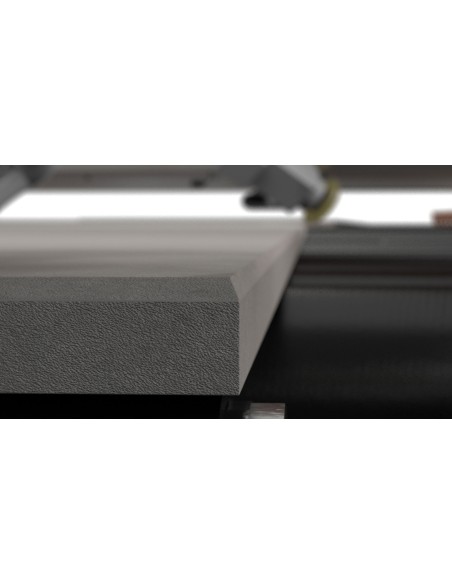

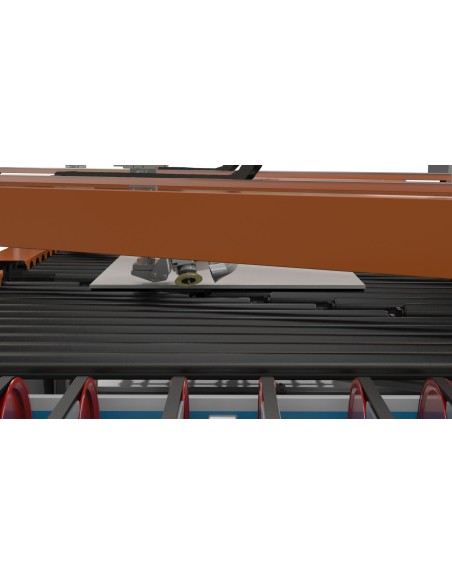

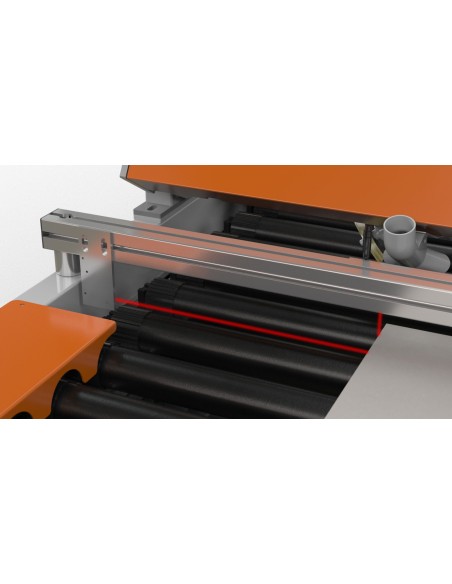

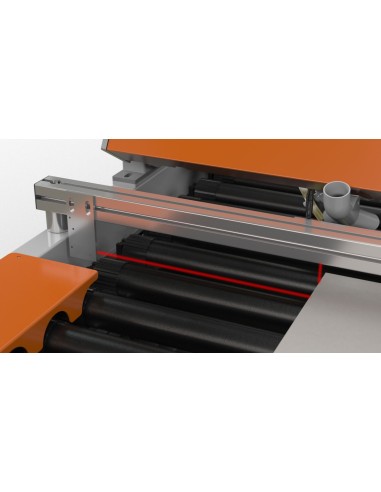

What makes this system unique is its deburring heads, which automatically adapts to the slab or tile. Photoelectric sensors detects the angle and position, relaying the data to the PLC, which adjusts the head position before deburring.

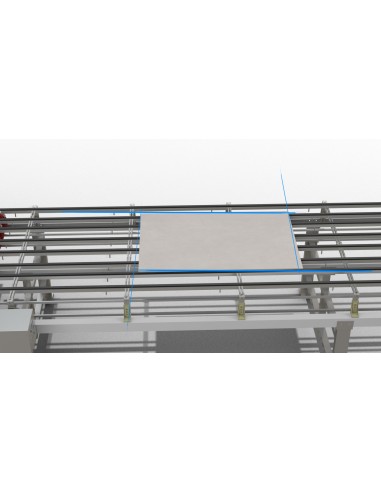

Compact and versatile, the machine can be installed at various points along the production line, such as at the dryer exit to clean press burrs or at the end of the line to clean edges after traditional and/or digital glaze applications.

During size changes, the operator simply selects the desired format via a touch interface (Industry 4.0 compatible), and the deburring process is fully automated.

Este sistema garantiza un mayor rendimiento del producto acabado y está disponible en tres versiones, con anchos de hasta 2000 mm.